Business Unit

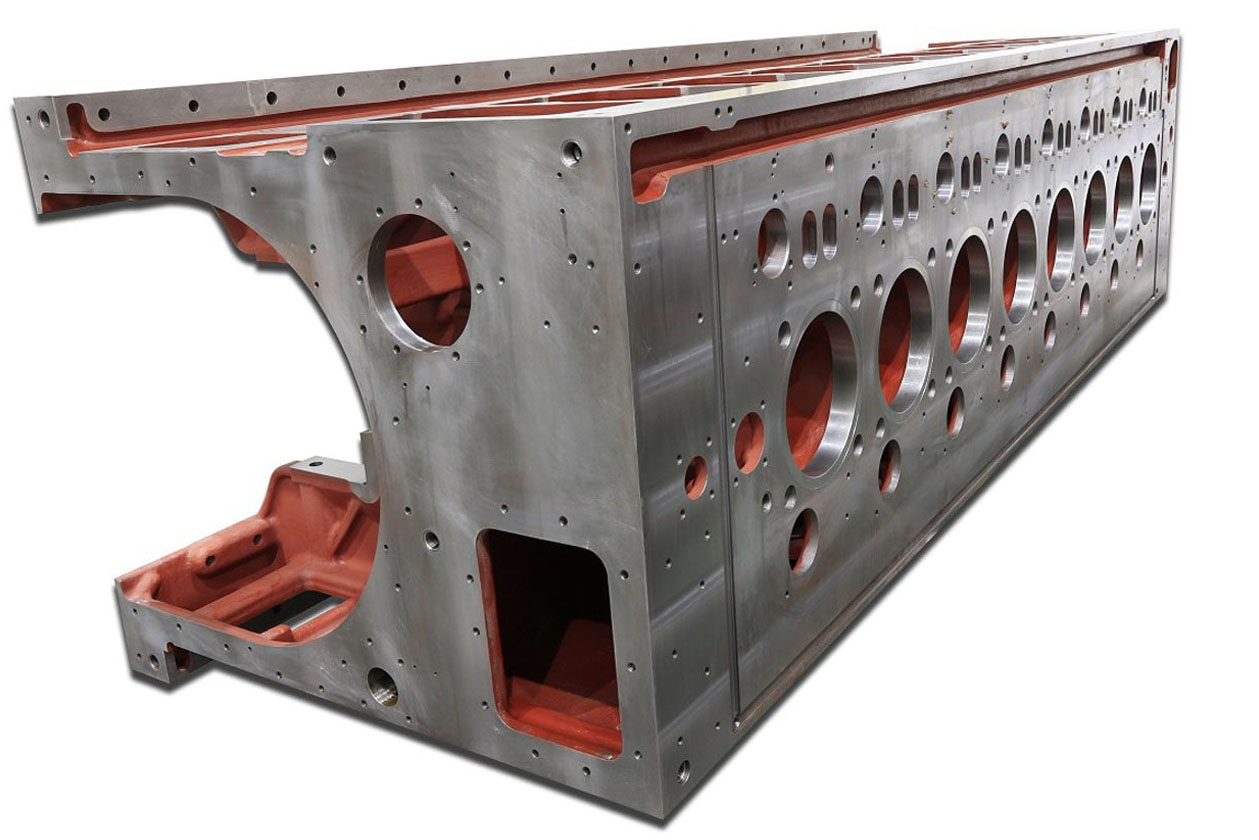

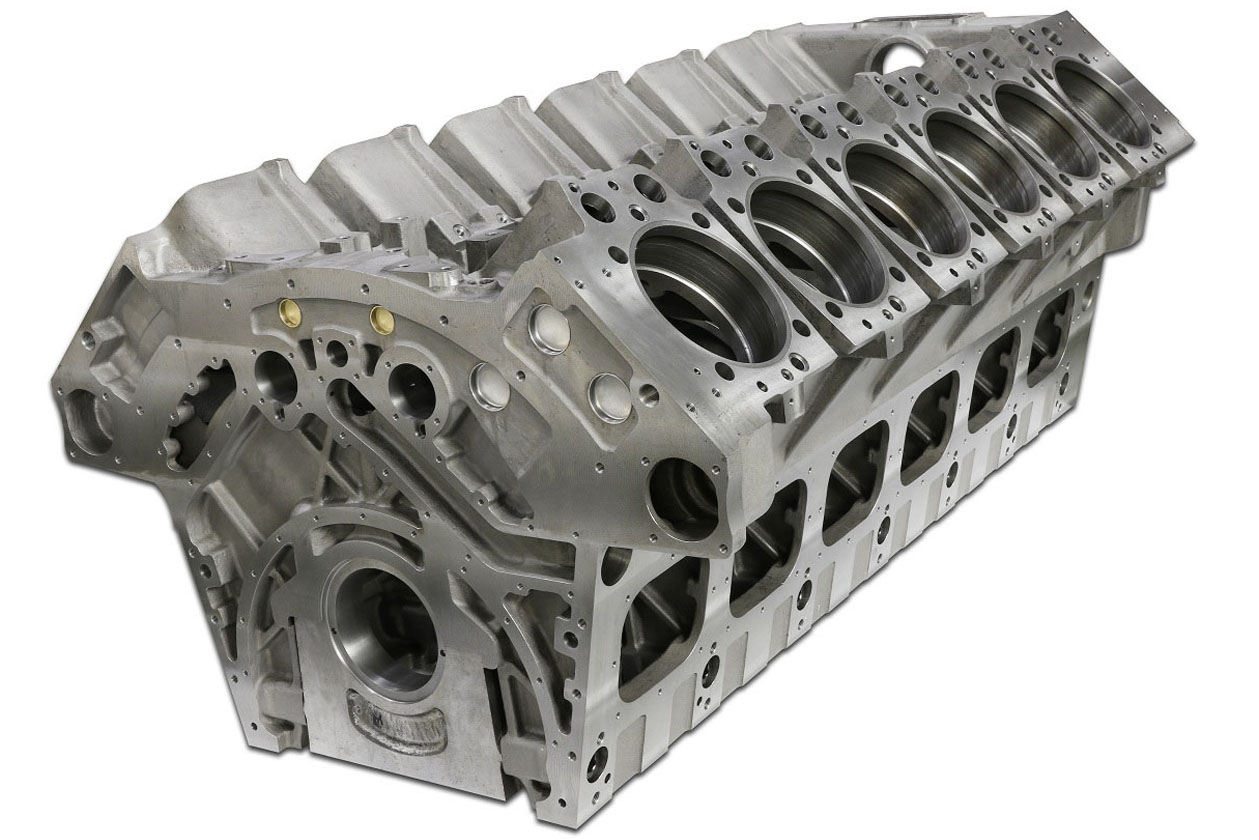

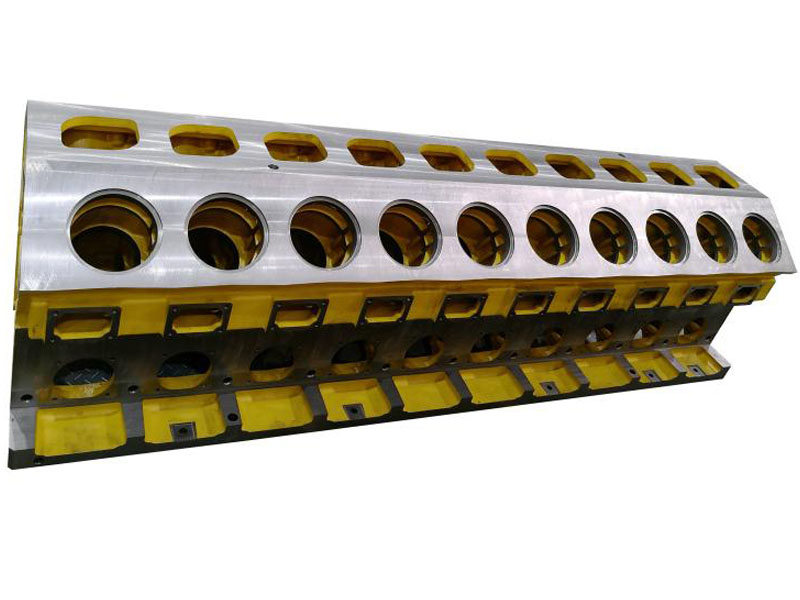

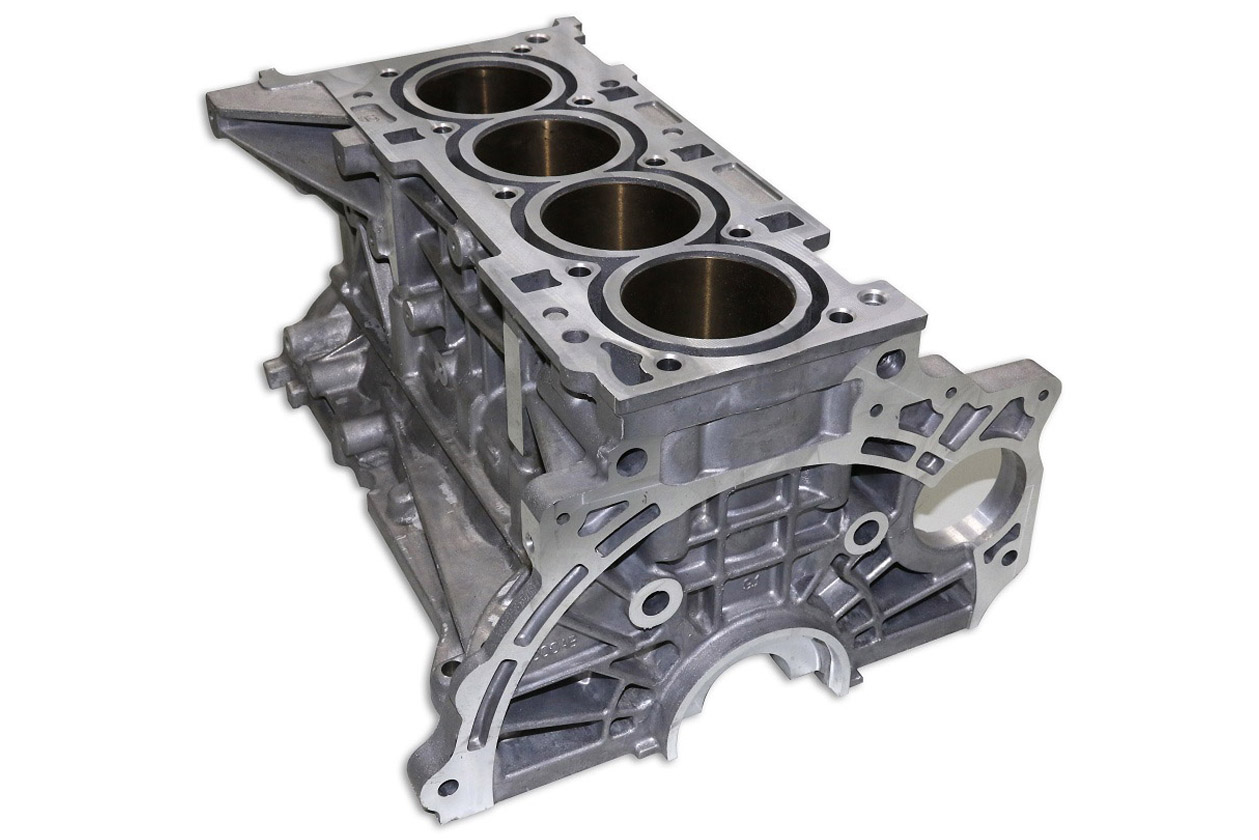

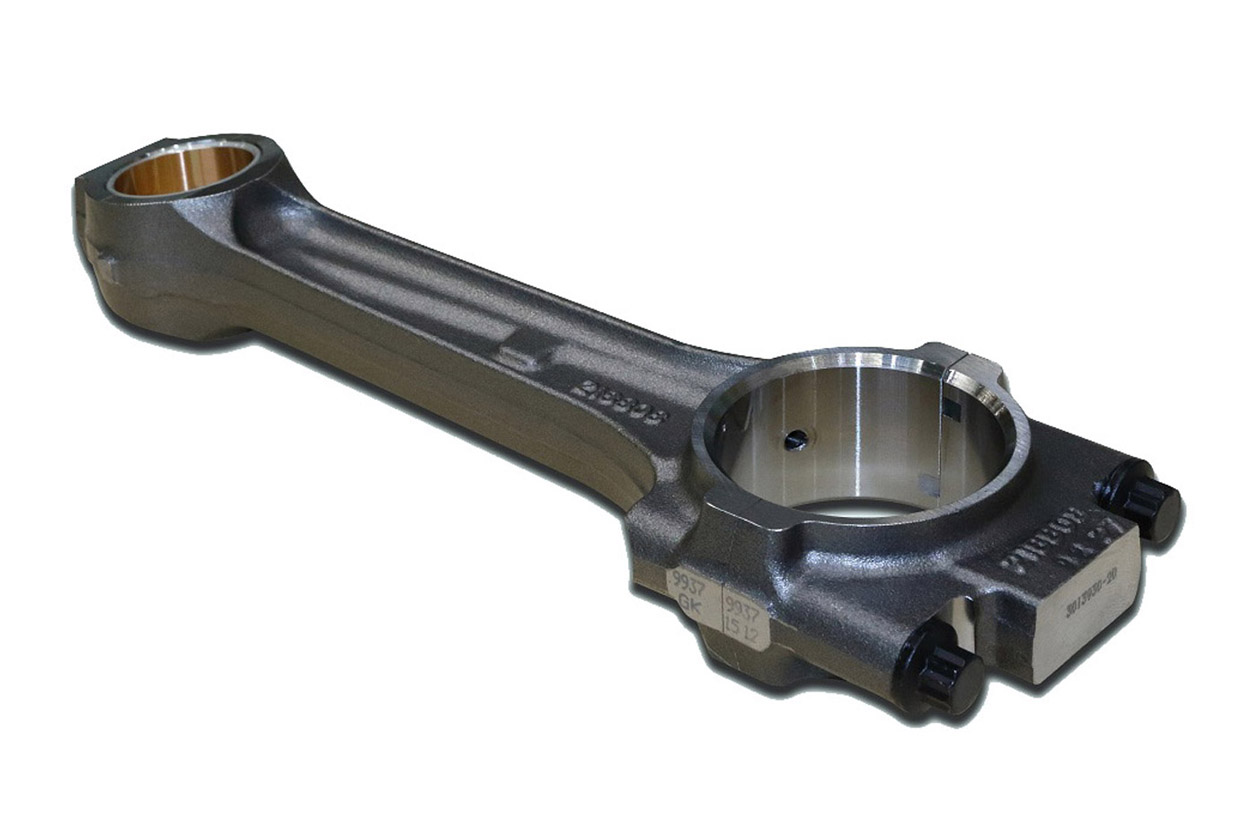

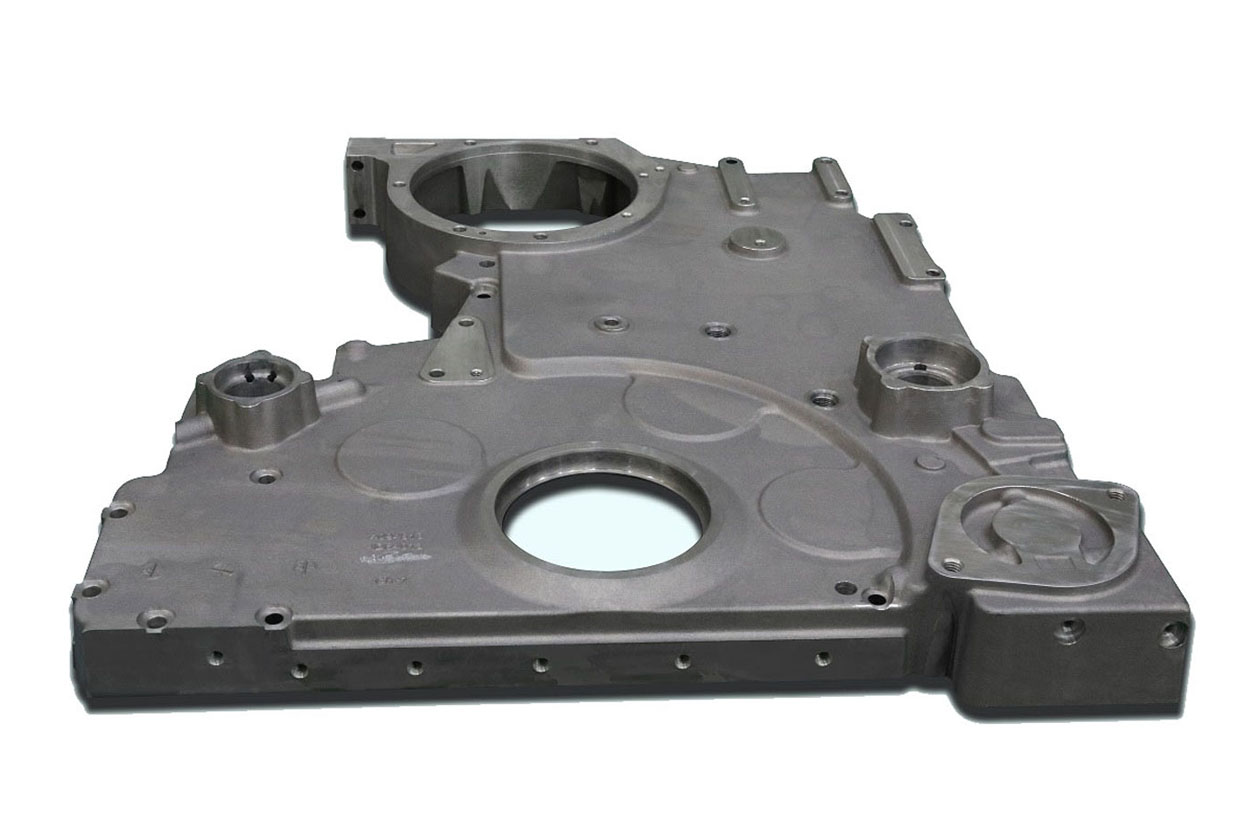

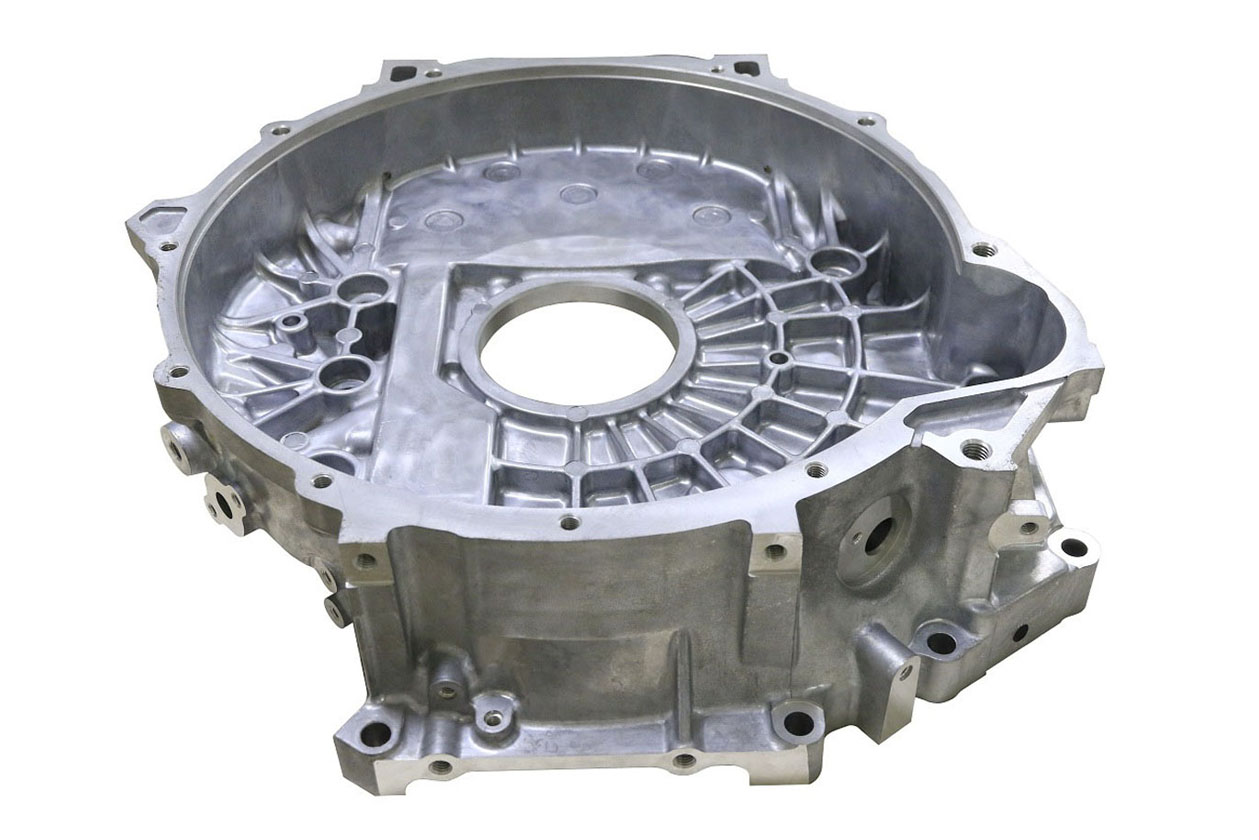

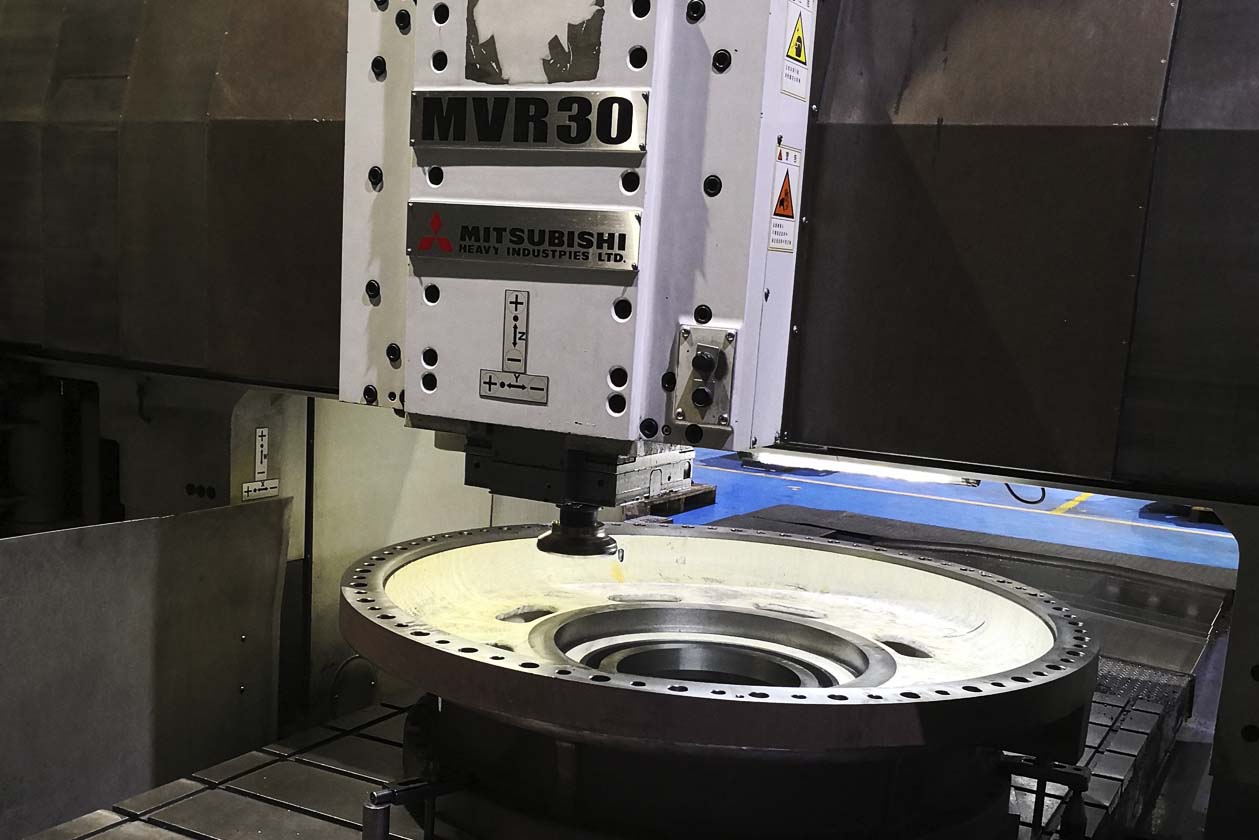

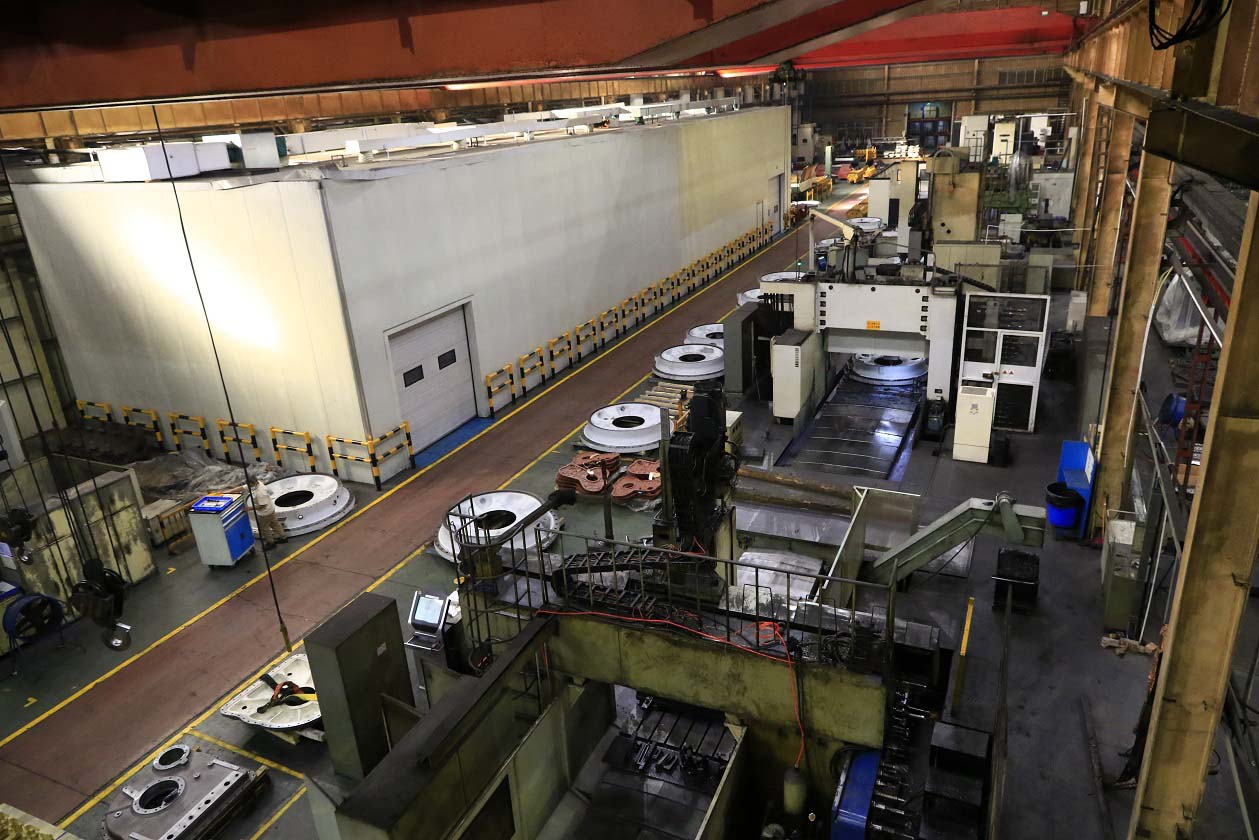

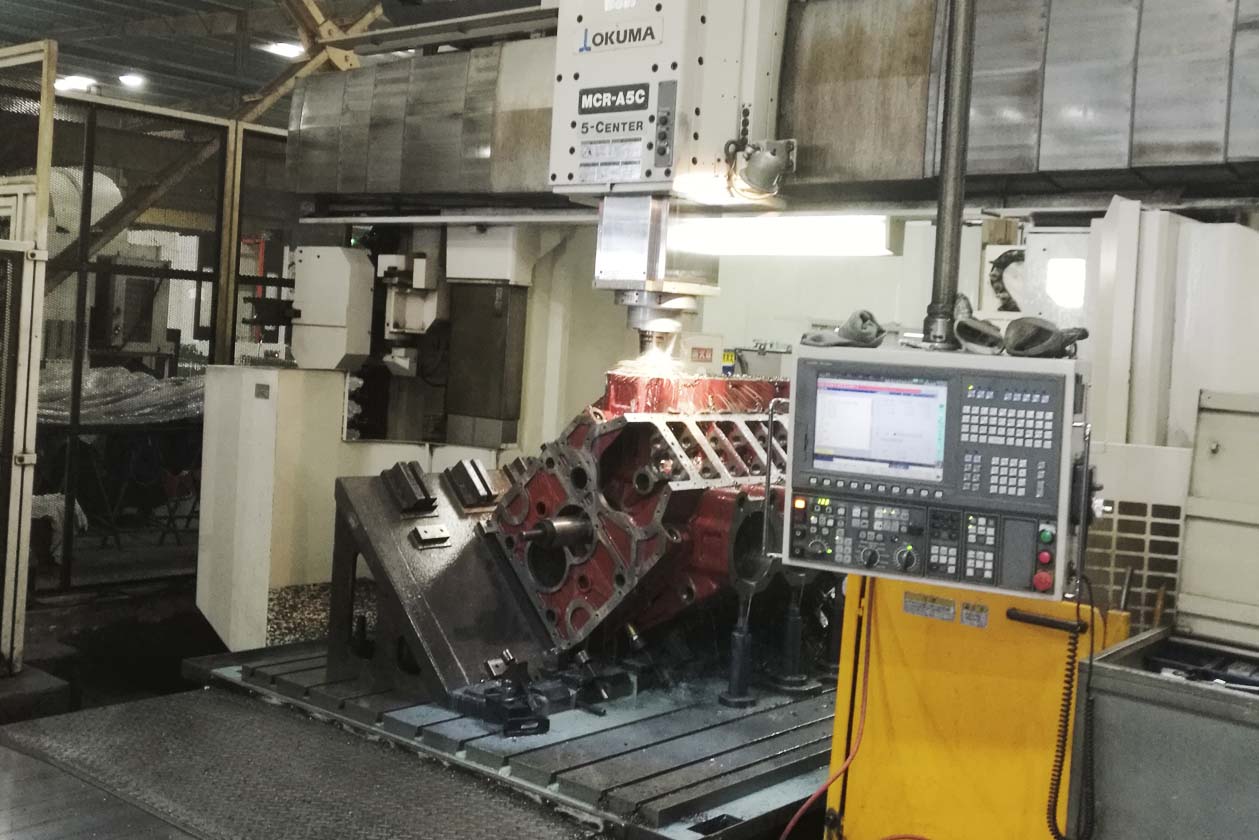

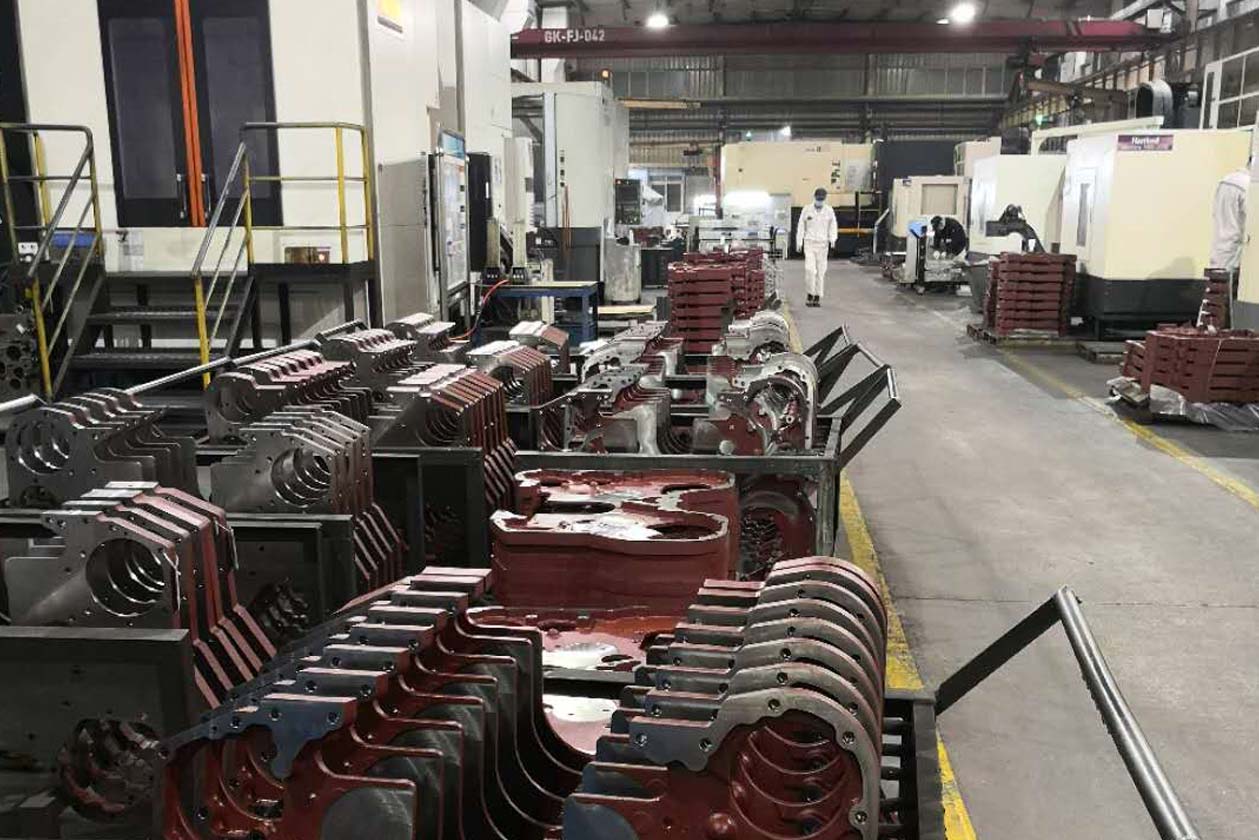

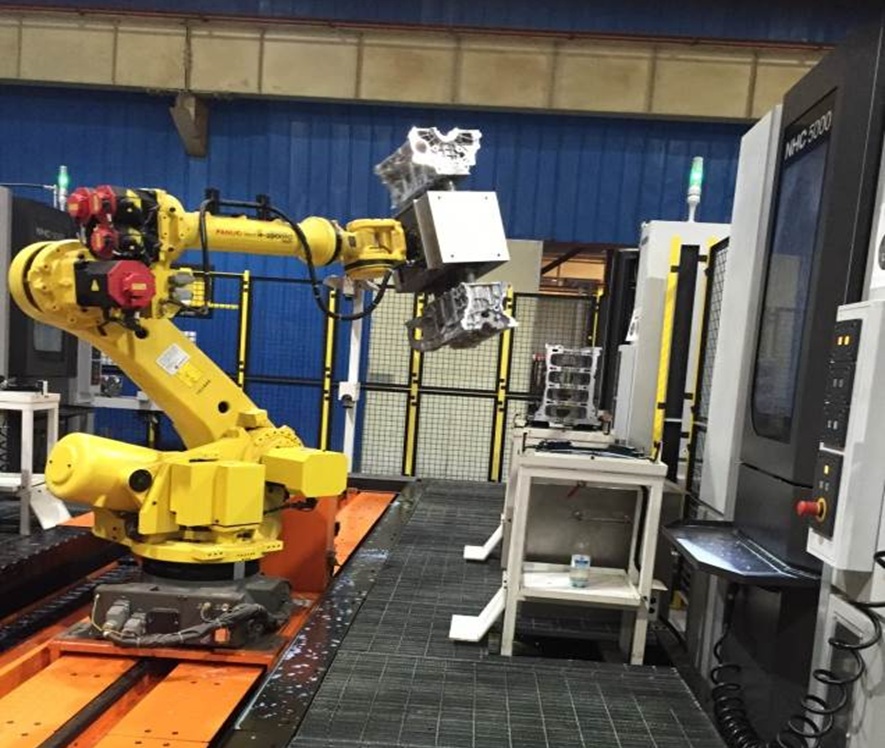

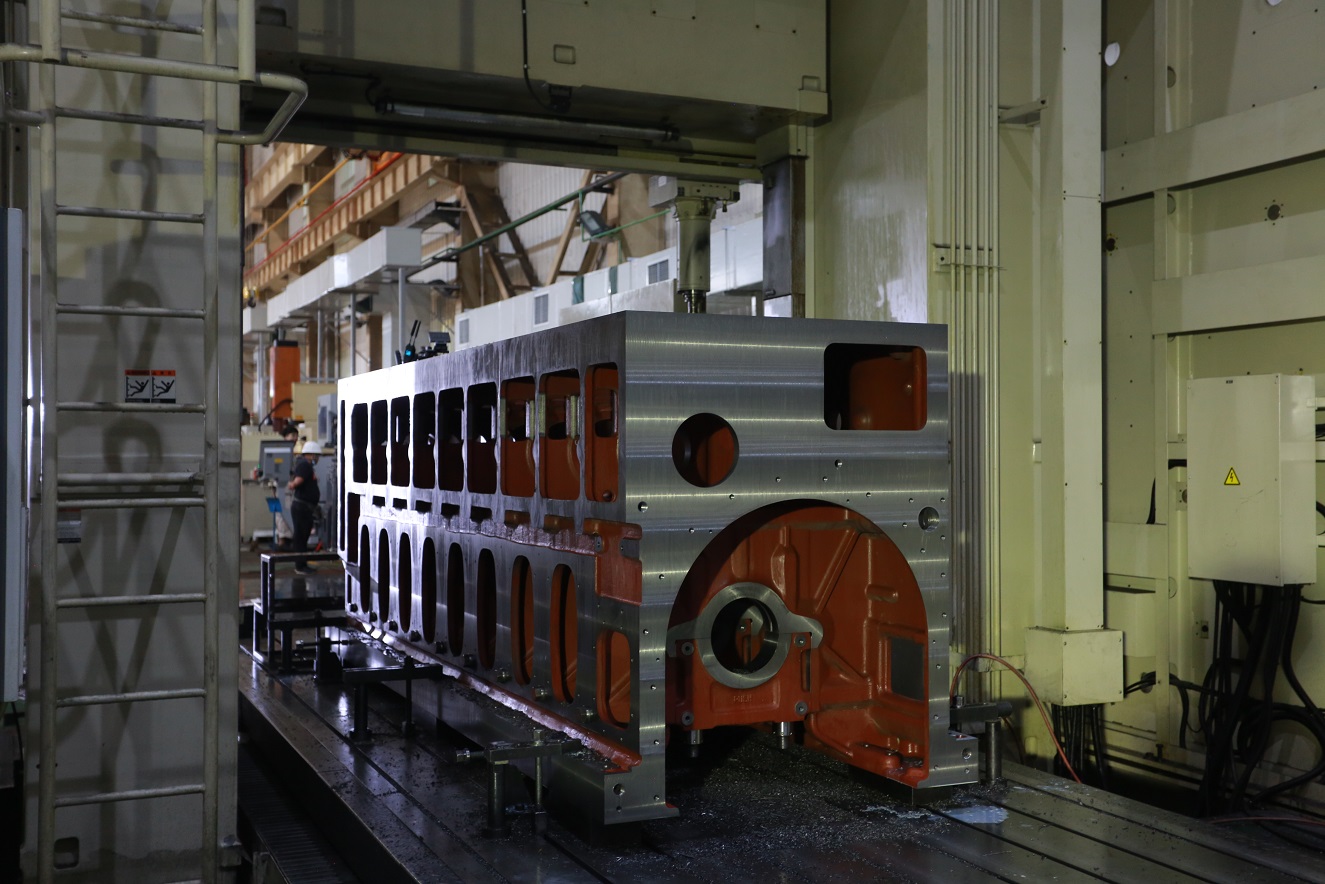

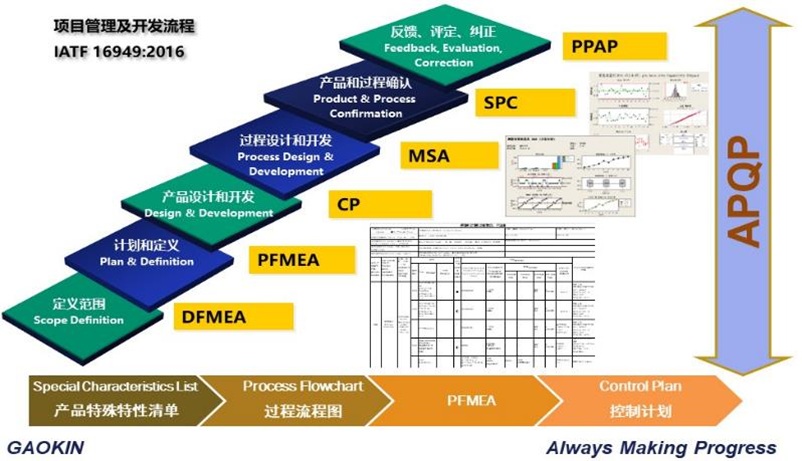

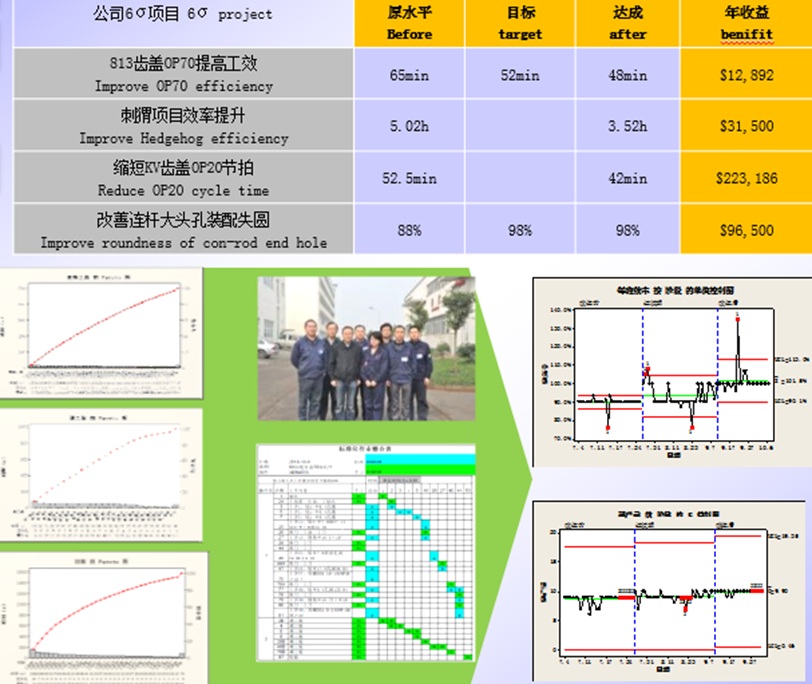

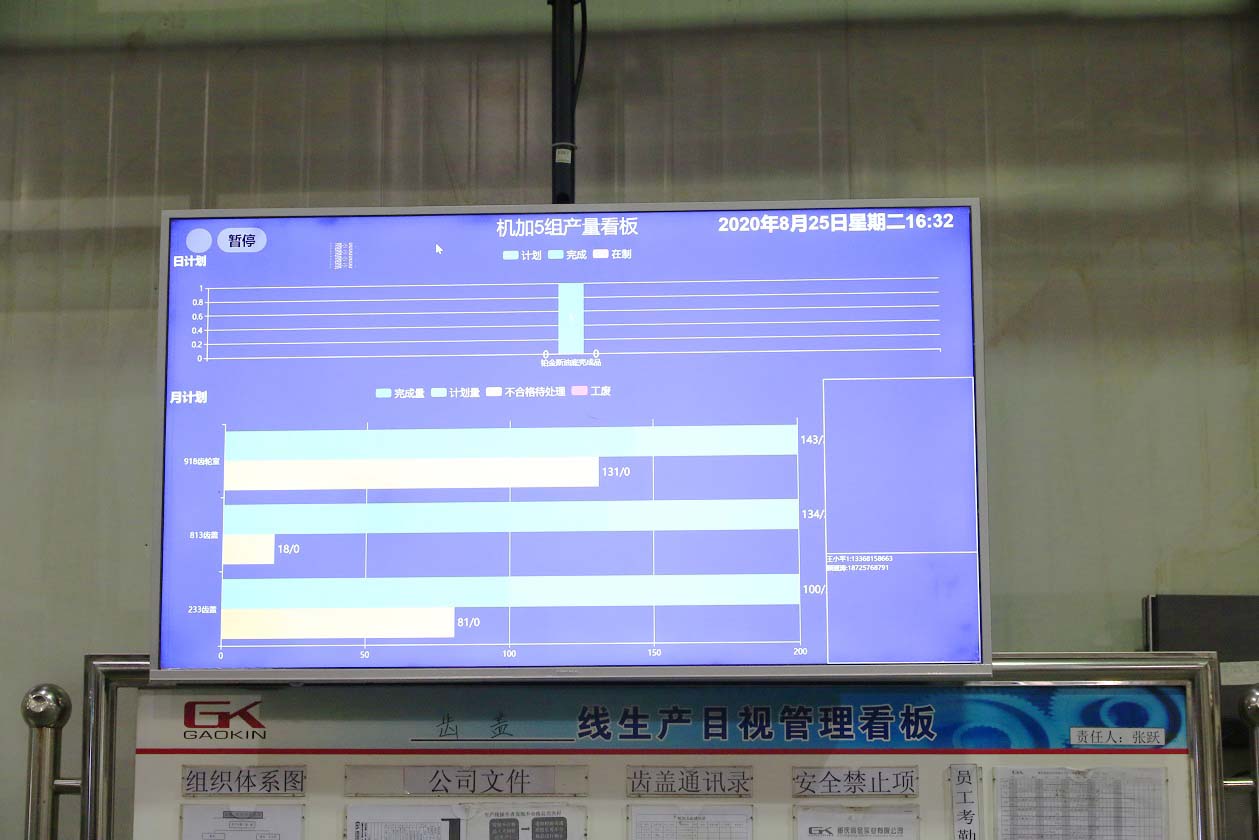

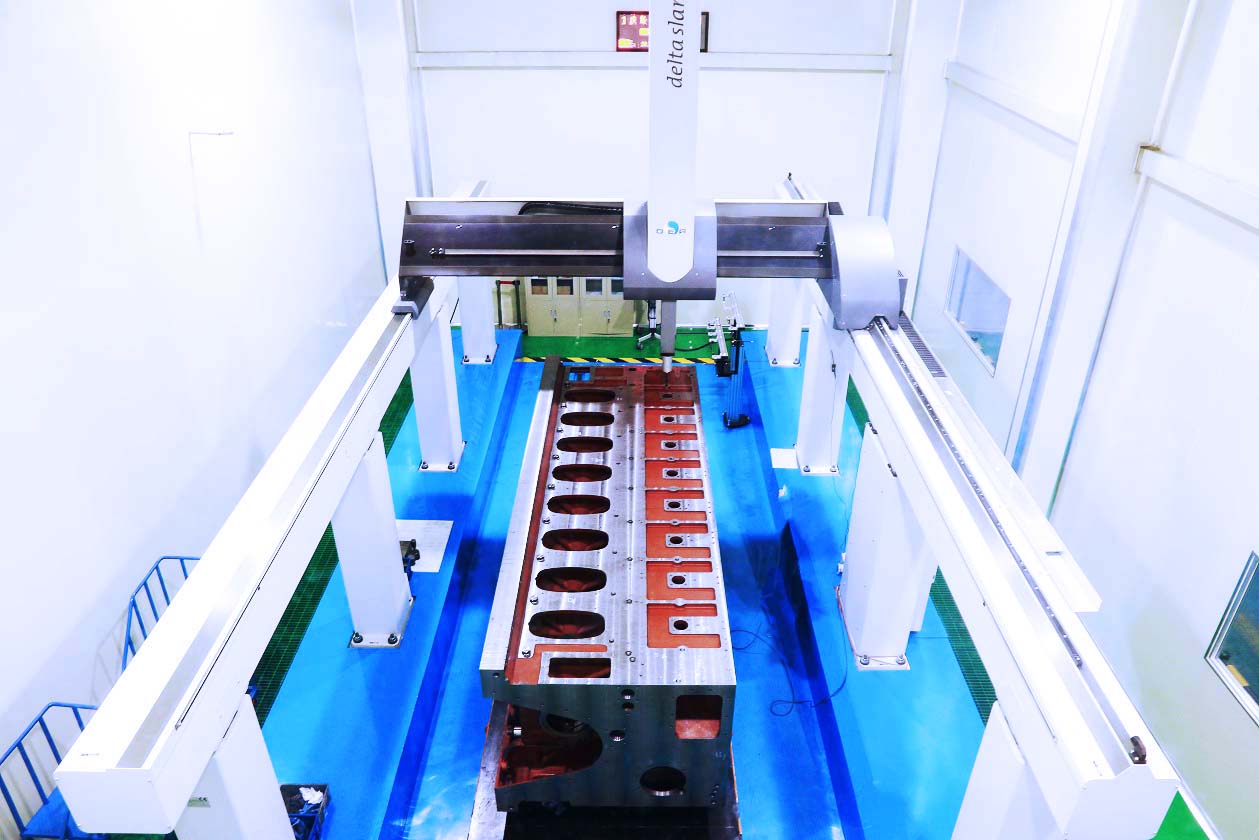

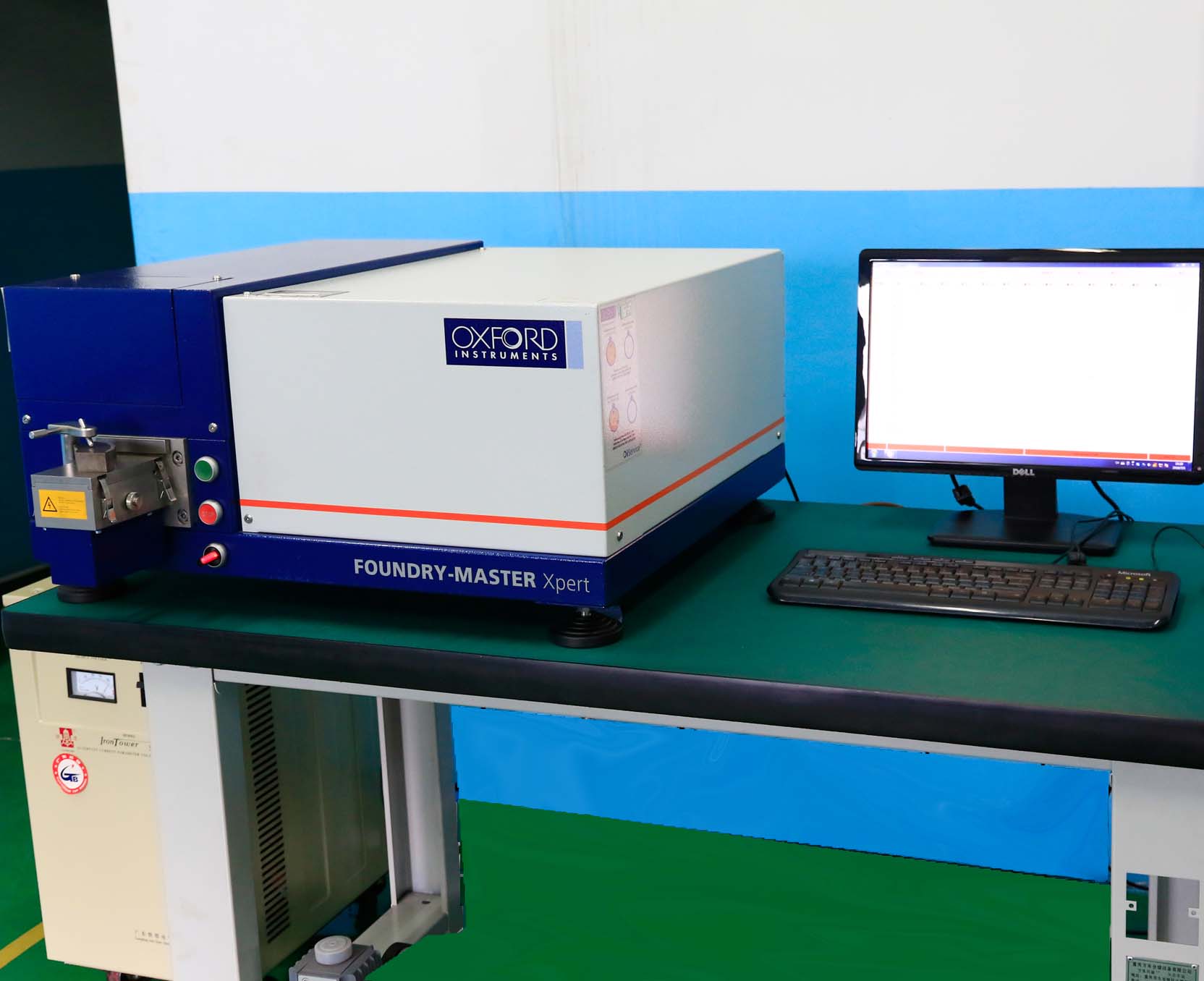

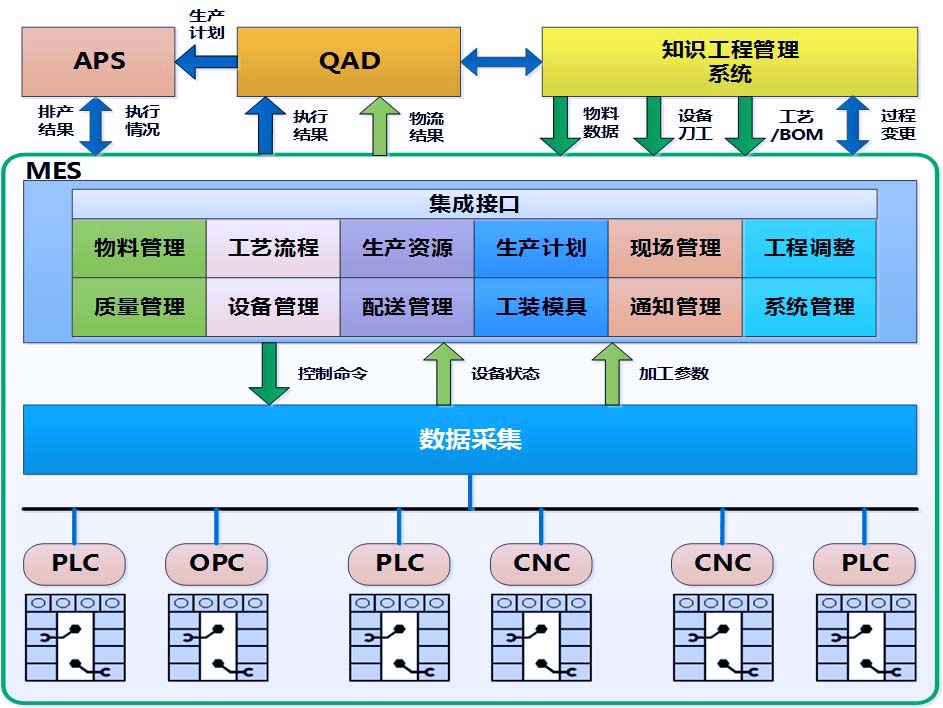

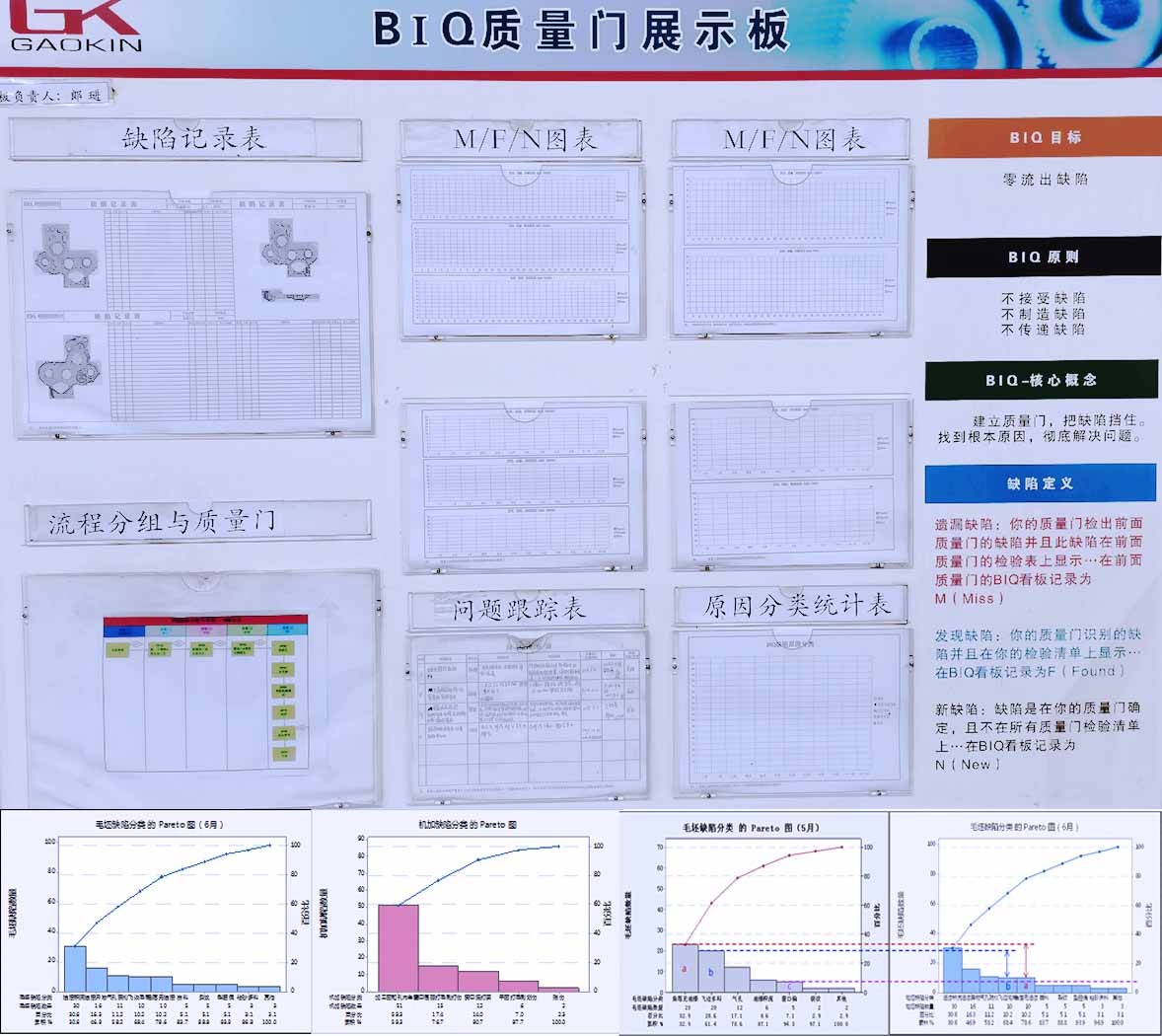

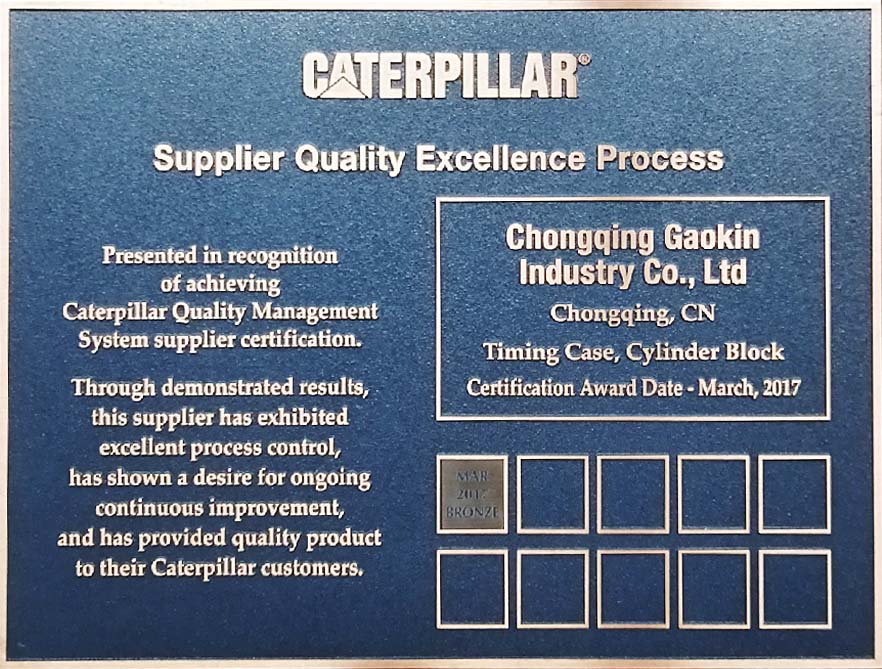

Founded in 2006, Precision Machining Business Unit has over 200 sets of imported and domestic high precision CNC machines and inspection equipment, which serves components to such industries as large horsepower diesel engine, wind power, oil & gas, printing machinery, etc. As a leading component manufacturer of large horsepower diesel engine in China, Gaokin can provide engine block, cylinder head, connecting rod, gear cover, oil pan, gearbox housing, cam carrier, etc., which are delivered globally to countries like United States, British, Canada, Germany, Austria, Romania, Brazil, etc. Being a leading vertical integration solution provider of high-precision, sophisticated and critical core components of power system, Gaokin has become strategic suppliers of multinational corporations like Cummins, Caterpillar, General Electric, etc., and been honored as “The Best Supplier of Cummins” and “Caterpillar SQEP Silver Supplier” for many years consecutively.